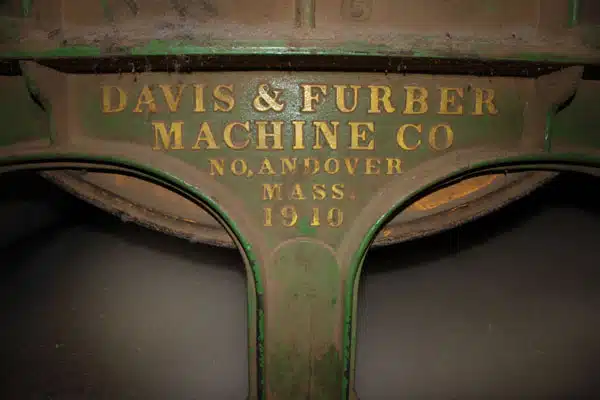

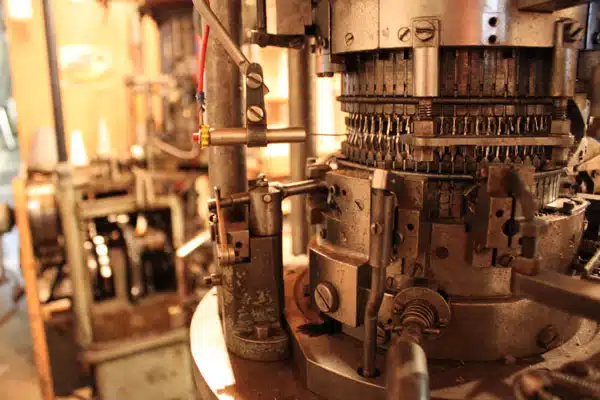

Our wool is produced on machines dating back to 1886.

Custom Woolen Mills started in 1975 as a small family business and, now in its second generation, has grown from producing 40,000 lb/year to 100,000 lb/year.

Check out the Calgary ShawTV Farm Fresh Tour of Custom Woolen Mills.

We are pleased to once again offer self-guided tours in the mill during our open hours. An easy day trip from Calgary, you'll get a chance to see our historic equipment at work.

For self-guided tours, we can accommodate a party size of up to 8 people. If there are other large parties already in the mill, you may need to wait a few minutes for your turn.

To get the most out of your yarn factory tour, we recommend visiting between 8 am and 2 pm. After 2 pm, most of the mill is closed down for cleaning.

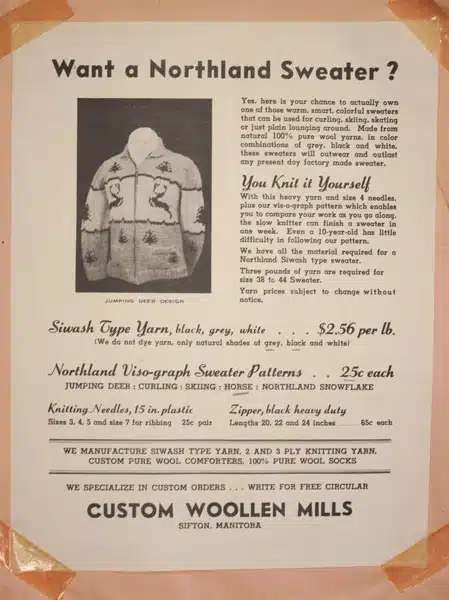

Custom Woolen Mills is the amalgamation of two small mills; one from Magrath, Alberta and one from Sifton, Manitoba.

Our machinery from Magrath, AB, started out as the Golden Fleece Mill, which ran from 1939 to 1956. The mill manager, John Moors, bought the machinery when Golden Fleece closed and started running it under the name Wool Carding and Spinning. Moors had been in the industry since he was 13 years old when he was hired as a bobbin boy for T. Eaton Co. in Ontario. He was 74 when we bought the machinery from him in 1975.

John Weselowski and Willard McPhedrain started the mill together in 1937 under the name Spin-Well Woollen Mill. Weselowski was the technical man behind the business, and McPhedrain, the finance guy.The other half of our machinery came from Custom Woolen Mills of Sifton, Manitoba.

They had a falling out, and McPhedrain moved away with the name, and Weselowski started over with Custom Woolen Mills. We eventually bought the machinery from Anna Weselowski, John's widow, and moved it to Alberta.

In 1975, Custom Woolen Mills Ltd Wool Carding and Spinning was born, though we use the moniker Custom Woolen Mills Ltd for short.

Producers bring raw wool to us to process. It is called raw wool because it has just been shorn off of the sheep.

Producers shear the sheep at least once a year. The result is a fleece that weighs between 5 and 10 pounds depending on the size and breed of sheep and has fibres between 1 1/2 to 5 inches in length. Wool that contains a small amount of vegetable matter can be cleaned without the heavy use of chemicals.

For more information about where our raw wool comes from, read our blog, The Canadian Wool We Use and How it is Grown.

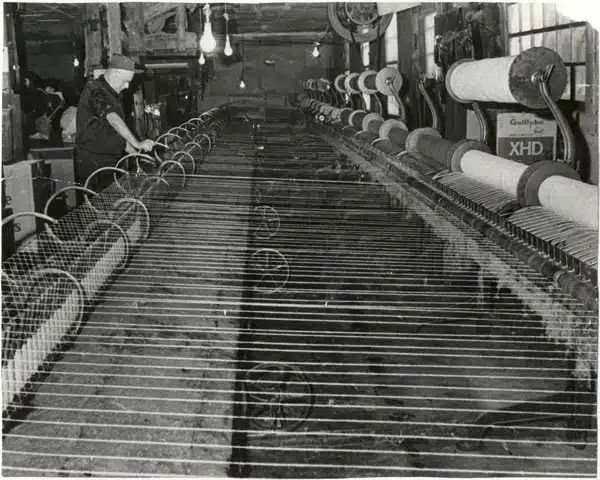

The Custom Woolen Mills wash system is originally from the mill in Sifton, Manitoba. We start by hand-sorting the raw fleece and feeding it into a "duster" that pulls it into tufts and allows short wool fibres, dirt, and vegetable matter to drop off into a collection bin.

The tufts of wool are then fed into what is called a two-bowl wash system; a wash tank with detergent and a rinse tank with pure water. We use a mild, plant-based, readily biodegradable detergent to help remove dirt and manure that may be in the wool.

Wool grease (or lanolin, when refined) is a secretion from the sheep's sebaceous glands that is present in raw wool. Most of the wool grease is washed out by using water heated past the lanolin melting point (120F). The wool fibres, dirt, and vegetable matter from the duster collection bin and the manure that settles to the bottom of the wash tanks are later combined with straw and composted. Wool is high in nitrogen content and creates excellent compost that also holds moisture.

Once the wool is washed, it is put in a centrifuge to spin out excess water and then dried.

Dyeing is the process of adding colour to textile products like fibres, yarns, and fabrics, using natural dyes made from pigments found in plants or bugs, or chemical dyes synthesized in the laboratory.

Chemical dyes were first synthesized in 1856 and facilitated the widespread use of colour in textiles. Prior to that, natural dyes were used and played a large role in the cultural significance of colour. Fabrics dyed from hard-to-obtain colours, such as red, purple, and blue, were reserved for royalty, while more common yellows, tans, and greys were allowed to be worn by anyone.

Black, grey, and brown sheep were important for their unique wool but were also unusual because a black sheep is a genetic throw-back. Most sheep raised for wool today are white in colour to facilitate commercial dyeing.

At Custom Woolen Mills, we still use natural grey and black sheep shades in our craft wools and yarns.

In addition, we dye wool using chemical dyes and some natural dyes to produce over 50 different colours. We do our dyeing in an old, double-walled milk tank that has been converted to have steam run through it rather than refrigeration. We dye in batches of 50lbs or 100lbs at a time; this means that the wool is dyed while loose, prior to carding or spinning. When time permits, we also do some hand-dyeing, fibre painting, and eco-printing for our online wool shop and brick-and-mortar retail store out here at the mill.

In 2014 we began establishing several demonstration gardens of different natural dye plants. Featuring both perennial and annual plants that give a range of colours from burnt red to aqua blue, the gardens connect us to the long history of dyed textiles.

Wool carding is the process of brushing wool with wire teeth to align the fibres. Wool carding machines were developed in 1748, and before that, processing was done by hand as a "cottage industry".

The carding machines currently in use at Custom Woolen Mills were all built in the U.S.A. and date from 1895 to 1927. They are used to card roping, batts, and spools of yarn for spinning. Our original batt carding machine, which is now being prepared as a display piece, was built in the 1860s and came from England.

Industrial revolution spinning technology started in the late 1700s with the invention of the “Spinning Jenny”, a foot-pedalled machine that allowed for many bobbins of yarn to be spun at the same time, rather than one at a time by a spinning wheel or drop spindle.

This technology evolved into the “Spinning Jack”, a mechanical machine that could spin over 100 bobbins at a time but required an operator to hand-crank the yarn onto the bobbins.

In the late 1800s, further modification created the fully mechanical “Spinning Mule”, the mainstay of commercial spinning until the mid-1900s.

Custom Woolen Mills is the only woolen mill in Canada that still uses a Spinning Mule for commercial yarn production.

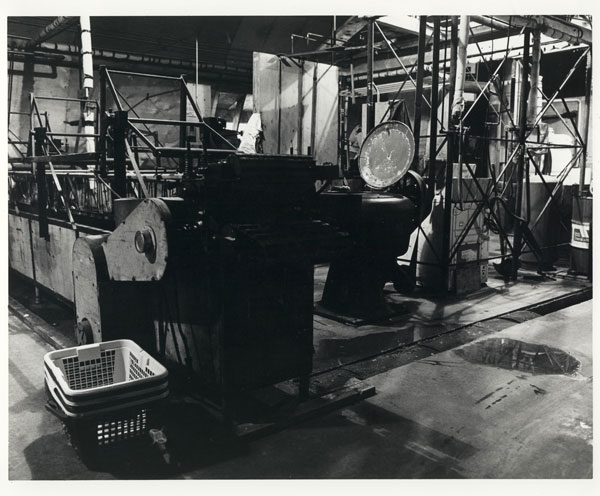

Our spinning mule was built in 1910 and is currently set up to spin 192 bobbins at a time. We purchased it from John Moors, in Magrath, Alberta, who worked on Spinning Mules most of his life – starting as a bobbin boy at the age of twelve and continuing to operate them until his retirement at the age of 74.

Mule spun yarns feature unique characteristics. In contrast to worsted yarns, which are spun on spinning frames with constant tension, mule-spun yarns are drawn, spun, relaxed, then wound about six feet at a time. This gives them a lively, fluffy quality similar to hand-spun yarns. Many experts consider the mule to make the very highest quality of handwork yarns.

We also spin on a Whitin Long Draft Roving Frame (circ. 1945) to make our soft-spun yarns and to ply the mule-spun yarns.

Custom Woolen Mills' yarns are especially suited for hand-knitting. Hand-knitting and the various precursors to it have been practiced for thousands of years by cultures all around the world. We work with many hand-knitters in our area to offer a variety of hand-made goods in our online and retail stores.

We're also pleased to make machine-knit socks.

The first recognized double-cylinder knitting machine (a not-so-distant relative of the machines used at Custom Woolen Mills) was created around 1900. Prior to 1900, wool-processing mills would pay hand knitters to knit their own brand of goods and give them special "knitting recipes" to knit to.

Custom Woolen Mills uses a William Spiers model knitter built prior to 1917 as a demonstration machine, and we do all of our production on '50s and '60s models of Bentley Komet machines. The Bentley Komets can produce a sock in three to ten minutes.

Custom Woolen Mills also demonstrates the home knitting machines built in the early 1800s and 1900s, called “hand-crank knitting machines”. There are many different makes of hand-crank knitting machines, some now harder to come by than others. Most famously, they were made widely available in Canada during the world wars. People could use the machines to make socks for the war effort, and after they filled a certain quota, they could keep the machine. Unfortunately, good quality metal was not available during the war, so many wartime knitting machines are now warped and do not knit very well.

Custom Woolen Mills' 100% wool fill comforters, mattress pads, sleeping bags and pillows have been sewn in the same way for over 70 years.

Our quilting machine was invented and hand-built by John Weselowski in 1945 at his Sifton, Manitoba mill. The distinct stitching pattern is unique to Custom Woolen Mills and is a cherished symbol of our all-natural bedding products. We sew between six and ten comforters a day, depending on the size.

Take a journey through history with a visit to our woolen mill just outside of Carstairs, Alberta. Our self-guided knitting tours are perfect for both avid knitters and history buffs alike. Explore the past century of wool processing and see historic turn-of-the-century machinery in action.

Contact us to plan your unique and educational knitting trip today!